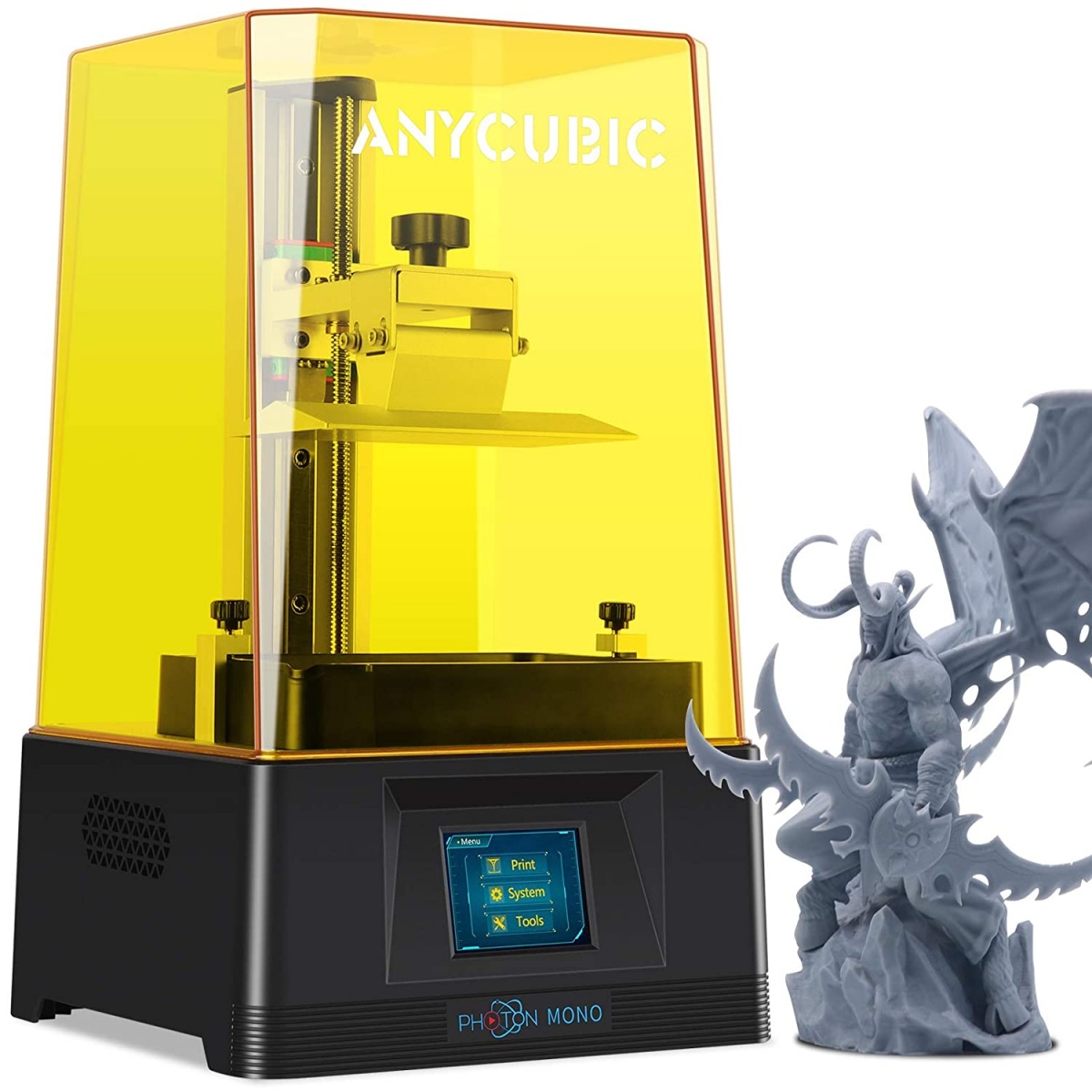

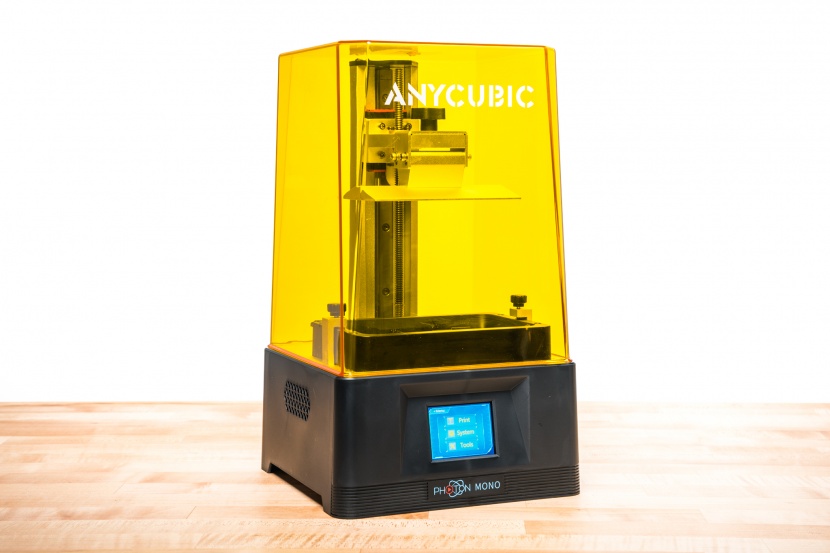

Anycubic Photon Mono Review

Our Verdict

Our Analysis and Test Results

One thing to consider when looking at a resin printer is that the procedures for layout, orientation, and supports differ wildly from filament printers, so you should be prepared for some trial and error when you are just starting out — even if you have a decent amount of filament-based 3D printer experience already.

Print Quality

The Mono did exceptionally well in our benchmark tests, including a model of the Eiffel Tower, a spiral tower with stairs, a hollow statue, some small figurines, a skull, and an icebreaker ship.

The Mono did decently well in our figurine print, but some of the thinnest features warped just a bit more than with some of the other ones. However, just about all of the other small features are very well-defined, even with the bridges and overhangs. The Eiffel Tower looks almost flawless, though it seems some of the smallest gaps got overexposed as they were filled — even after being thoroughly cleaned before post-curing.

The tower and the rook both came out great, with smoothly curving sections and small details that are defined very well. The words at the top were readable as well.

The icebreaker ship and the trio of smaller figurines also came out great, though the skull model had some smaller gaps that were unintentionally filled in.

Ease of Use

The Anycubic Mono —- like most resin printers -— didn't fare the best in this category, simply because of how difficult it is to deal with the material and post-processing of your prints.

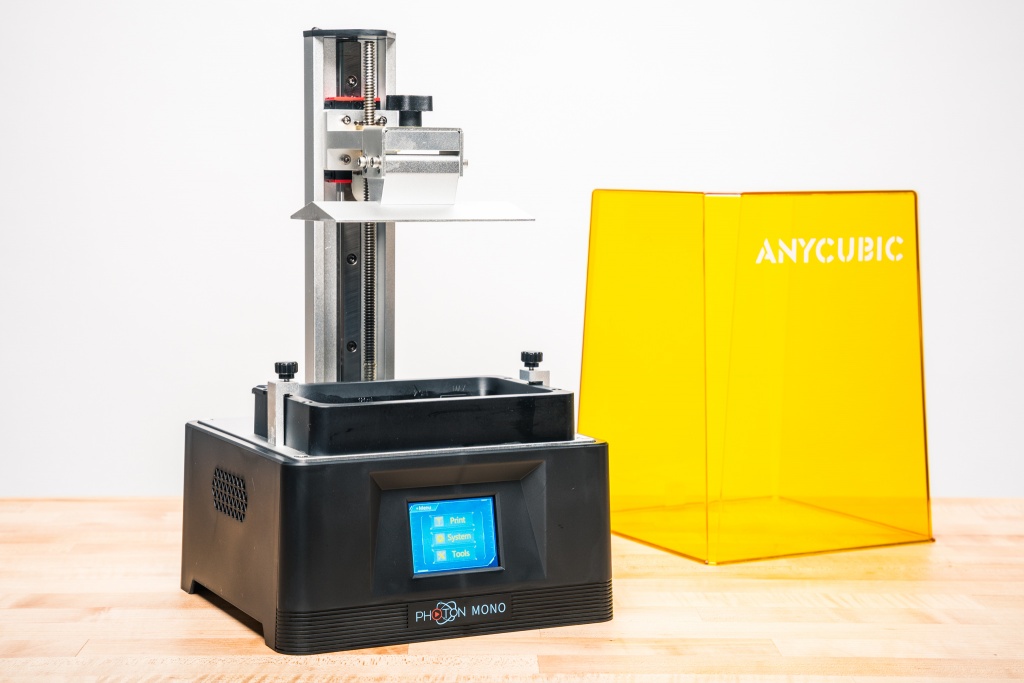

Luckily, it is easier to level the build plate on the Mono than many of the resin printers, as you just loosen the retaining screws, lower it down until it holds a piece of paper against the screen, re-zero it, and tighten the retaining screws. We generally found this to be much quicker and easier than a filament printer, where you are dealing with three or four different adjustment screws. It is also very easy to load resin, as you simply pour it into the vat — being careful not to overfill — and you are ready to go.

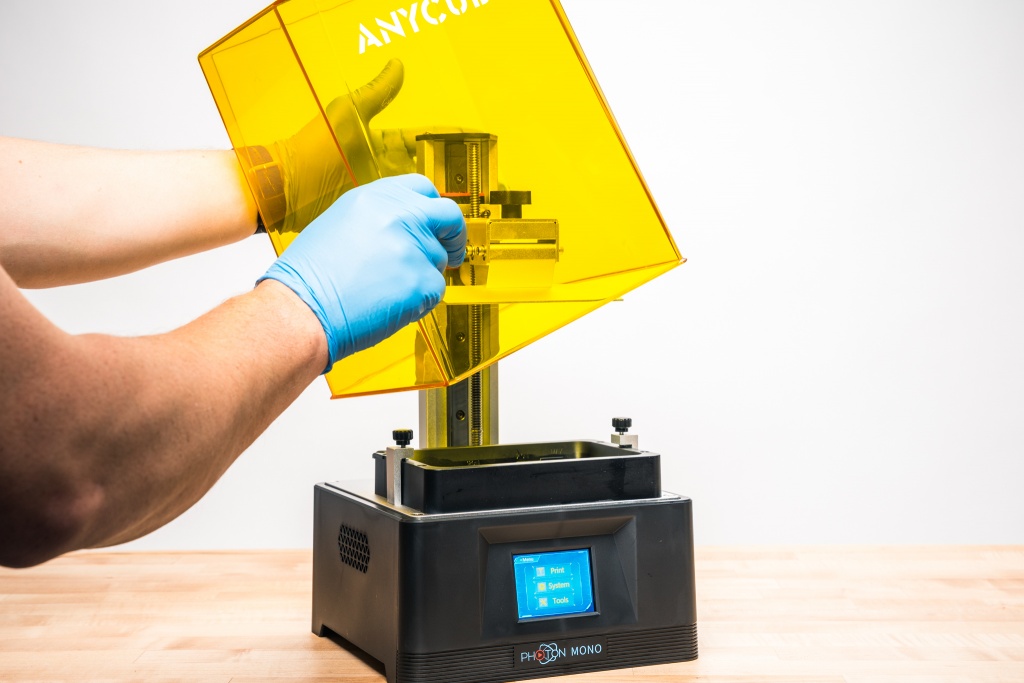

However, one of the reasons that makes resin printers more difficult to use is the need to clean them, which usually involves proper PPE and isopropyl alcohol. You'll also need to fully clean and wash your finished prints to remove uncured resin, then post-cure them under a UV light source for the resin to fully react and reach its peak mechanical properties.

All of this cleaning and curing leads to considerably more consumable materials that you need to have on hand to safely and effectively use your Mono, like paper towels, disposable gloves, isopropyl alcohol, and resin filters. On top of all that, placing the supports in the slicing software for your resin printing models can also be a bit of an art form. This isn't an insurmountable amount of work by any means, but it is an order of magnitude more effort than most filament printers in our experience.

Print Capabilities

The Anycubic Mono has average print capabilities. It is compatible with the free Anycubic slicer, as well as a few other free and paid programs. We used the Anycubic slicer for testing and found it to be just about as easy to use and as capable as the typical resin slicing software.

The build volume on this printer is a little on the smaller side, topping out at 130mm x 80mm x 165mm. The build plate is anodized aluminum, and we didn't struggle with bed adhesion issues.

We like that this printer is compatible with any 405 nm curing resin, whether made by Anycubic or a third-party supplier.

Support

Customer support for the Mono wasn't the best. We couldn't find much helpful information on setup and troubleshooting, and the manufacturer was not very responsive to our questions.

We found a few videos on the website that walk you through some maintenance and component replacement but not too much that actually deals with the slicing/printing/cleaning process.

They have a contact form to fill out but limited other ways to get in touch with customer service. We also found it to be quite difficult to elicit a response from them in our experience, so you might want to choose a different printer if you were planning on having a responsive manufacturer to regularly rely on.

Value

Fortunately, the Mono is one of the more budget-friendly options out there. However, you do need to consider the cost of all the consumables when you are looking at its value.

Conclusion

All in all, we think the Anycubic Mono is a great budget-friendly option for anyone trying to create very detailed prints on a smaller scale. There is a bit of a learning curve and a higher amount of effort required per print but you can get some downright astonishing prints on a miniature scale once you get the hang of it. It's not as versatile or beginner-friendly as a filament printer though, so beginners might want to check out some other models first.