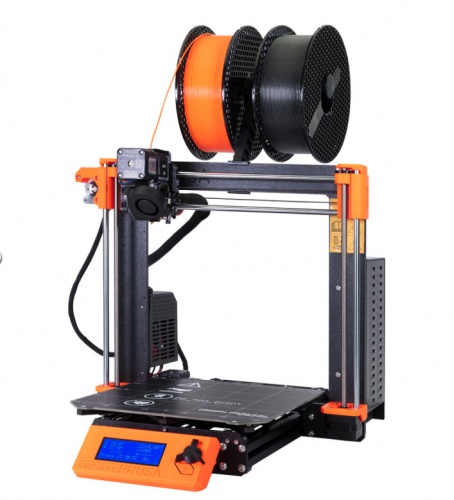

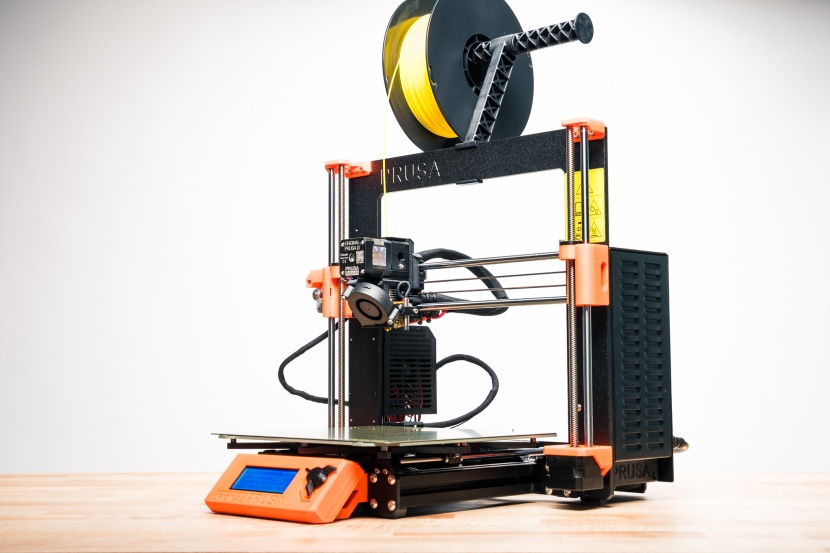

Prusa i3 MK3S+ Review

Our Verdict

Our Analysis and Test Results

This printer is also available in a kit form for a significant reduction in price, making it a good option for someone who doesn't mind taking on a DIY project in order to save some cash.

Print Quality

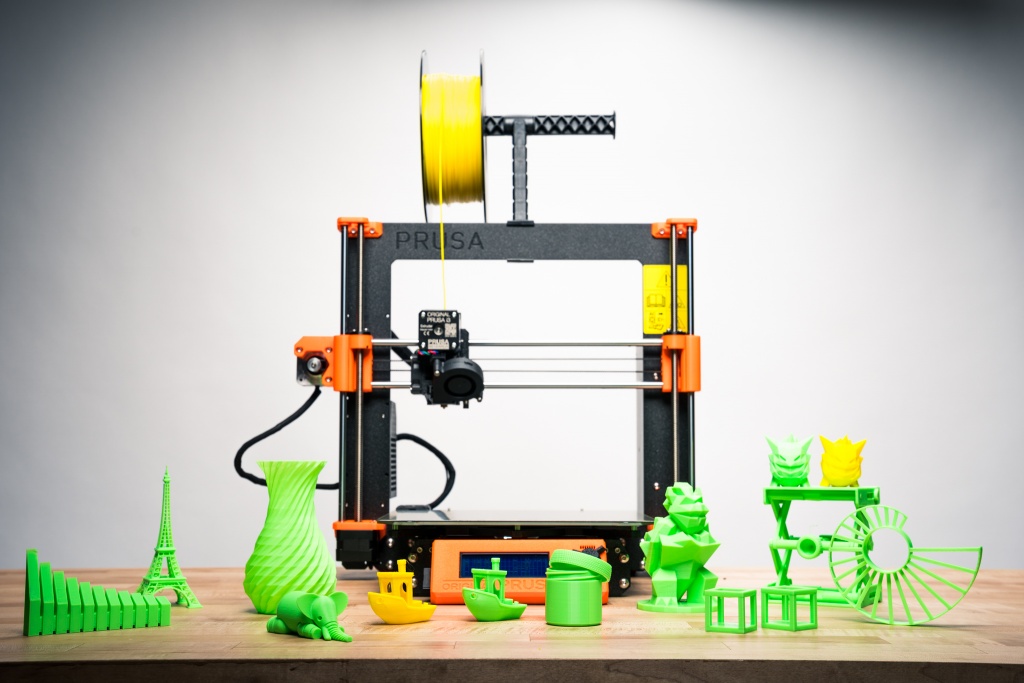

The i3 MK3S+ did exceptionally well in terms of print quality, showing clean geometry and overall appearance on each model we printed.

We started by making a 3D benchy — a fairly ubiquitous printer calibration/torture test in the shape of a tiny tugboat. This printer did an excellent job with the PLA version of this print, with smooth surface finishes and clean overhanging geometry. The finer details are also very clear. The quality of some of the smaller details degraded a bit with the ABS version, and some of the overhangs had a slight sag, but the overall print was still above average.

The i3 MK3S+ also did ok with very fine details and unsupported geometry. With PLA filament, it handled bridging like a champ. However, the ABS version of our bridging test kept failing, with the print separating from the raft prematurely. This printer also struggled quite a bit with the Eiffel Tower in both types of plastic, failing every time we tried it. However, it rebounded by creating a smooth, unsupported surface in even the steepest overhangs.

The i3 MK3S+ did very well with clearances, printing an elephant with legs that could move freely and a clean surface finish. However, this printer didn't do the best with the with the coin test; we attempted to print a cavity the size of a nickel, but the opening was just a bit larger than the coin, which would explain why the clearances were never stuck together.

Again, the i3 MK3S+ did exceptionally well when printing a PLA platform jack and wireframe cube, but it struggled with their ABS counterparts. The platform jack kept failing, and the wireframe cube warped a bit, with one side melting up and a small amount of sagging.

This printer produced an excellent pair of low-poly figurines from popular video games, in both types of plastic. The overhangs were smooth and the lines were crisp, with just a tiny bit of layer separation in the ABS versions. It also did extremely well with the single-layer, spiral vase in both types of plastic, making an essentially flawless print.

In our printed tower, we found minimal Z-axis wobble, and we were able to remove the temporary supports cleanly from both the PLA and ABS versions of the test, leaving behind a clean supported face.

Ease of Use

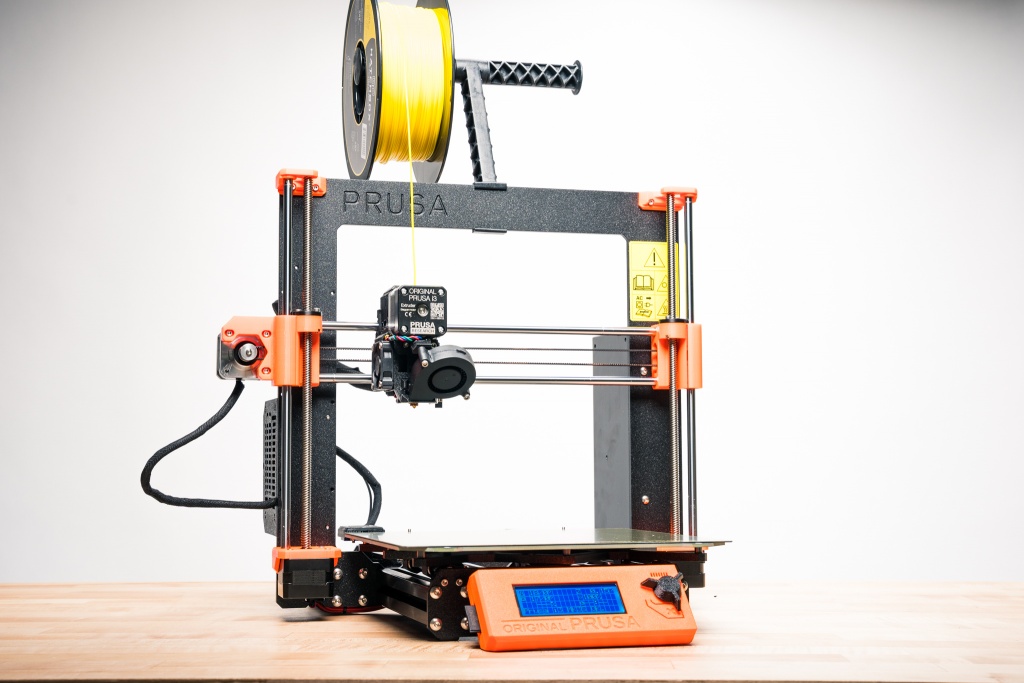

The Prusa i3 MK3S+ again did exceptionally well in our ease-of-use metric. This printer arrives completely ready to go if you opt for the assembled version, requiring you to simply plug it in and snap on the spool holder and you are all set. It even guides you through the setup process for your first print, walking you through the removal of the shipping holders and the test print from the factory.

We also love the fact that the printer automatically probes the bed and compensates for any unevenness before every print, meaning that you don't have to work through the rather tedious bed leveling process common on most other printers. The display on this printer shows the time elapsed, and files can be sent via a USB cable directly connected to a computer or by an SD card for standalone printing.

This 3D printer has a practically completely automatic filament swapping system. The direct extruder makes it considerably easier, as you don't even need to feed the filament through a bowden tube. You just select the option on the menu, give time for the hotend to heat up, and then the extruder motor will just about do the rest. It will fully eject the old filament or grab the new filament with minimal help on your part — you just need to insert the end into the guide at the top of the extruder assembly, and it will do the rest.

Print Capabilities

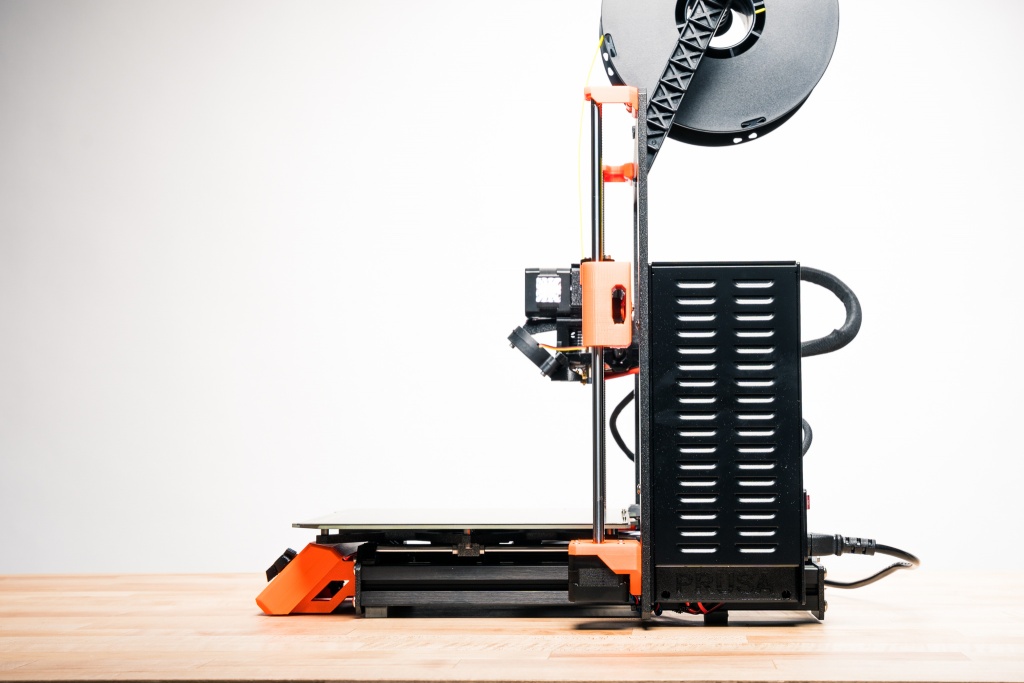

The Prusa i3 MK3S+ is a fairly versatile machine, and is compatible with a variety of different slicing software packages, including the free Cura program that we used for our tests, as well as the paid Simplify3D software. It has a moderately large build area of 250mm x 210mm x 210mm and we absolutely love the removable build surface. This smooth sheet tends to have excellent bed adhesion but is flexible enough to allow for easy removal of prints.

It has a pair of fans cooling the prints and the extruder, and is compatible with any 1.75mm filament that has a 300°C or lower melting temperature. This means that you can use a wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, HIPS, PP (Polypropylene), Flex, nGen, nylon, carbon-filled, Woodfill, and other filled materials. The bed can also reach a maximum temperature of 120°C to increase adhesion and minimize warps or layer splits.

Support

The Prusa i3 MK3S+ finished out with a middling score in terms of customer support.

Unfortunately, we didn't find any video documentation on the manufacturer's website but they do have plenty of detailed guides with photos. They have an email and a chat for reaching out to customer support if you have problems and seem decently helpful

Value

Unfortunately, the Prusa i3 MK3S+ is one of the more expensive machines that the typical person might be considering for personal use, so it probably isn't the best printer if you are shopping on a tight budget.

Conclusion

If you are searching for a top-tier 3D printer for home use, then we highly recommend the Prusa i3 MK3S+. It has excellent print quality and is very easy to use, with tons of convenience features. This printer has tons of guides to help you if you get stuck as well. All in all, this printer is one of our favorites and we definitely think it should be on your shortlist if you are searching for the best of the best.