When exploring your options in the world of kitchen appliances, you can easily end up overwhelmed with all the choices on the market. Our aim is to demystify the options and make your decision easier. We bought the top microwaves currently available and put them through the wringer to see which model came out on top. Our testing process is split into four different metrics, with a handful of sub-tests in each metric.

Heating

The most fundamental job of any microwave is to heat food effectively, and we dedicate the largest portion of our scoring to this critical metric. We've found that heating performance varies dramatically between models, with some creating dangerous hot spots while others leave cold zones that require multiple reheating cycles. Our heating performance tests are designed to reveal these differences through objective, measurable data. We also tasted the food we reheated to ensure that each microwave heated the best possible leftovers.

Pizza Reheating Test

Perhaps no food item better tests a microwave's real-world performance than leftover pizza. It's a challenging task that requires balancing multiple factors: the cheese needs to melt evenly, the crust should warm without becoming soggy or rock-hard, and the toppings must heat through without creating burning hot spots.

We use a standardized approach with slices of large cheese pizza, ensuring consistency across all tests. The pizza is stored overnight in the refrigerator, mimicking typical leftover conditions. We heat the slices for 45 seconds on high power, then immediately measure temperatures across multiple points using an infrared thermometer.

Heat Map Test

One of the most revealing tests in our arsenal is our heat map analysis, which visually demonstrates how evenly each microwave distributes energy across its cooking cavity. For this test, we use Kraft Jet-Puffed Marshmallow creme as our testing medium. Its properties make temperature variations immediately visible through browning patterns.

We begin by cutting parchment paper to match each microwave's turntable size exactly, then spread the marshmallow creme as evenly as possible across the entire surface. This preparation requires patience and precision, as any variations in thickness could skew our results. We then microwave the prepared sample on high power for exactly two minutes. If the marshmallow wasn't adequately cooked in this initial period, we continue heating in 30-second intervals until we achieve sufficient browning for analysis.

Using an infrared camera, we capture detailed images of the cooked marshmallow spread. What we're looking for is color consistency — ideally, the entire surface would display uniform browning, or at minimum, show a symmetrical gradient pattern. Models with rotating turntables generally perform better than those without, but we've found that turntable presence alone doesn't guarantee even heating. The quality of the stirrer fan and waveguide design plays an equally important role.

Heating Speed Test

Raw heating power matters when you're trying to quickly warm up your morning coffee or heat water for tea. Our heating speed test provides objective data on how efficiently each microwave converts electricity into heat energy. We use a standardized approach that eliminates variables: 125 milliliters of water in identical glass beakers, refrigerated overnight to ensure consistent starting temperatures.

We place the beaker in the exact center of each microwave and heat for precisely 45 seconds on high power. Using calibrated thermometers, we measure the temperature increase.

This test reveals more than just wattage ratings might suggest. We've tested 1000-watt microwaves that outperformed 1200-watt models, demonstrating that efficient design matters as much as raw power. Factors like cavity size, magnetron efficiency, and even door seal quality all impact heating speed.

Frozen Foods

Frozen food preparation represents a significant portion of microwave use in most households. From quick frozen dinners to properly cooking frozen vegetables, this capability can make the difference between a convenient meal and a disappointing dining experience. Our frozen food tests push each microwave to handle different textures, densities, and heating requirements.

Frozen Lasagna Test

Frozen lasagna presents one of the ultimate microwave challenges: a dense, layered dish that needs thorough heating without creating molten edges or frozen centers. We use commercially available frozen lasagnas, following each microwave's recommended settings when available, or package instructions for standard heating.

Using our array of temperature probes, we measured temperatures at multiple depths and locations. The best performers showed temperature variations of less than 15°F across the entire dish, while poor performers exhibited dangerous cold spots exceeding 40°F differences.

We pay particular attention to the corners and edges, which tend to overcook while centers remain cold. Microwaves with inverter technology or sophisticated power cycling generally performed better, as they could maintain lower, steadier power levels that allow heat to penetrate gradually rather than blasting the exterior.

Hot Pocket Test

The Hot Pocket test might seem less sophisticated, but it reveals important information about a microwave's ability to handle different food densities within a single item. The pastry exterior requires gentle heating to avoid becoming tough, while the filling needs thorough heating to reach food-safe temperatures.

We position three temperature probes at the left, center, and right of each Hot Pocket, monitoring temperatures throughout the heating cycle. The center typically heats slowest, so we watch carefully for the moment all three zones reach appropriate temperatures. Top-scoring microwaves achieved consistent temperatures across all three measurement points, with variations under 10°F.

Temperature spreads exceeding 30°F were common among lower-scoring units, creating the familiar but frustrating experience of simultaneously frozen and molten sections. We also evaluate taste and texture. The best microwaves produce a Hot Pocket with a tender crust rather than the leather-like consistency that plagues poorly heated specimens.

Defrosting

Defrosting might not be glamorous, but it's a crucial microwave function that can save significant time in meal preparation. Poor defrosting performance leads to partially cooked edges with frozen centers (a food safety hazard and culinary disappointment). Our defrosting test uses one-pound packages of frozen ground meat, providing a standardized challenge that mimics real-world use.

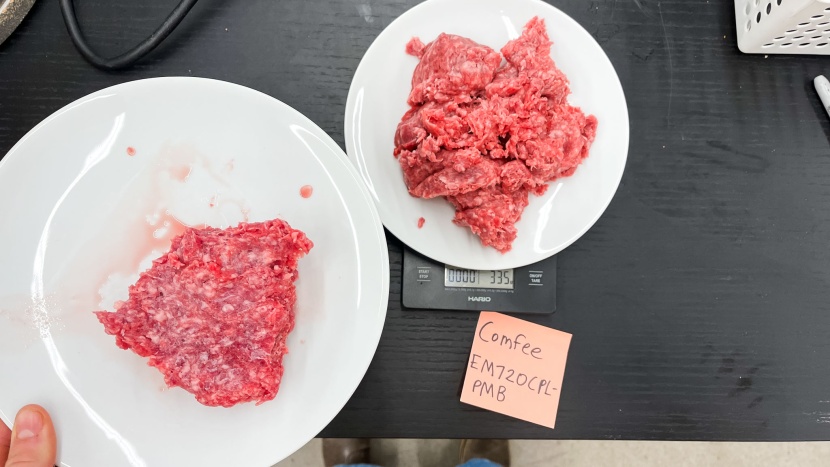

We start with fully frozen meat, stored in our testing freezer for at least 48 hours to ensure complete freezing. Each microwave's automatic defrost function is engaged, inputting the one-pound weight when prompted. If the microwave signals to flip or rearrange the meat during the cycle, we comply. Otherwise, we let the automatic cycle complete without intervention.

The scoring focuses on two critical factors: evenness of defrosting and avoiding any cooking. We carefully separate the defrosted portions from any remaining frozen sections, weighing each to calculate the defrosting efficiency.

Poor performers often began cooking the edges while leaving large frozen chunks in the center. The worst offenders left us with gray, partially cooked edges that would create texture issues in the final dish. We found that microwaves with sensor technology and inverter power systems generally excelled at defrosting, as they could maintain low, steady power levels rather than cycling between full power and off states.

Presets

While they constitute a smaller portion of our overall scoring, preset functions significantly impact daily usability. We evaluate both the availability and effectiveness of common presets, focusing particularly on the ubiquitous popcorn button that manufacturers specifically warn against using.

=Preset Availability and UsabilityWe catalog each microwave's preset options, noting which offer true one-touch convenience versus those requiring additional inputs. The best interfaces provide clear, intuitive access to common tasks. Does pressing “2” immediately start a two-minute cycle, or must you press “start” afterward? Is there a dedicated 30-second button for quick additions? These details matter during rushed morning routines or when your hands are full.

Popcorn Test

Despite package warnings to avoid the popcorn preset, we know most users rely on this convenient feature. We test with standard 3.0-3.2 ounce bags of Pop Secret Movie Theater Butter popcorn, evaluating multiple factors: cooking time, number of unpopped kernels, and any burning or scorching.

We time each popcorn cycle and count unpopped kernels from three separate trials, averaging the results. The best microwaves consistently produce well-popped corn regardless of minor variations in bag placement or starting room temperature. Models with sensor cooking technology generally outperformed simple timer-based presets, adapting to actual cooking progress rather than relying on fixed durations.