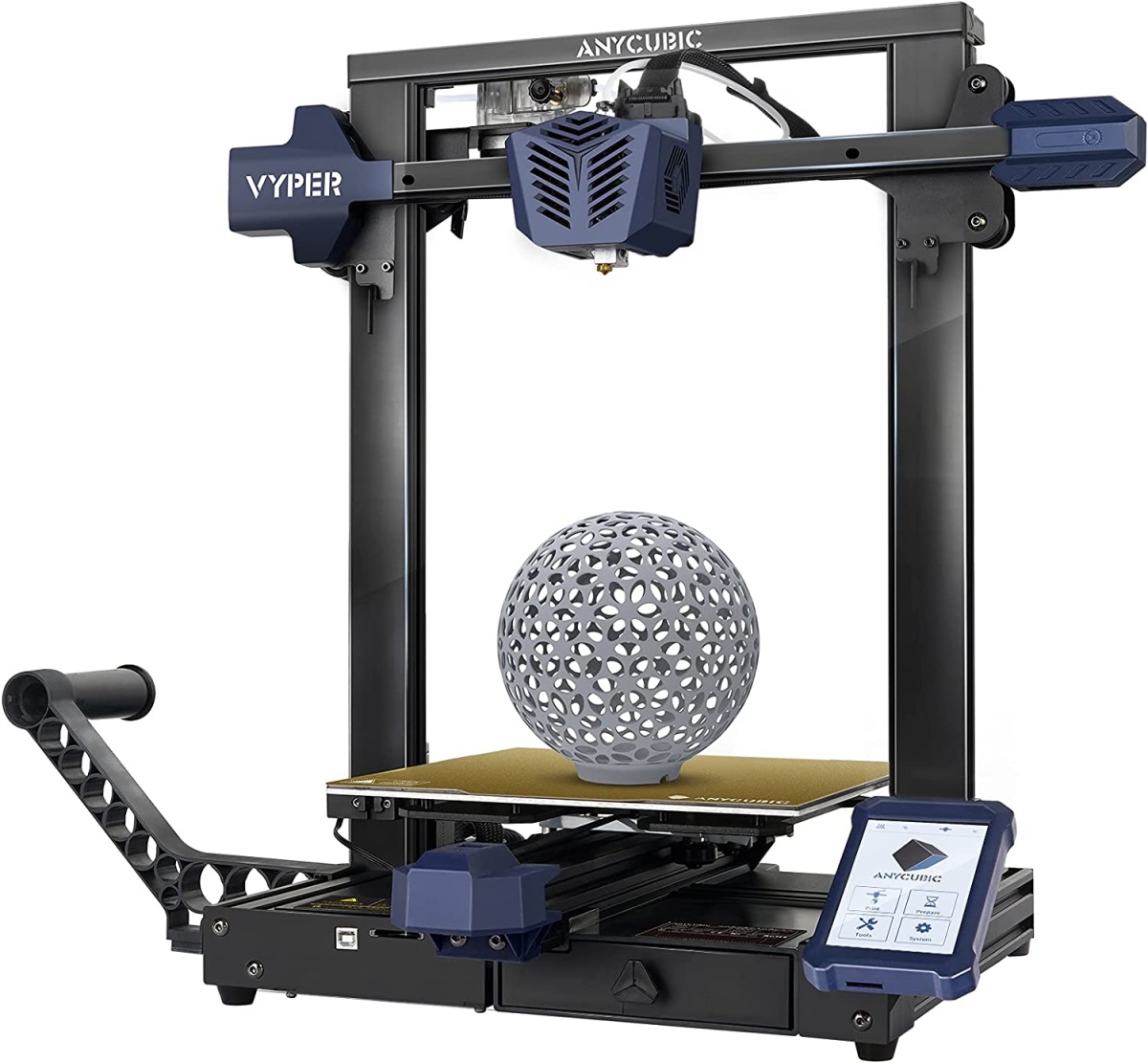

Anycubic Vyper Review

Our Verdict

Our Analysis and Test Results

The Vyper is undeniably a great value, performing well across the multiple test metrics — we didn't find much to nitpick. The specs and design are surprisingly impressive, and the ease of use ranks among the best in class; all backed by knowledgeable customer support and the reputation of one of the leading hobbyist brands on the market.

Print Quality

Bottom line: the Vyper produces prints of admirable but not incredible quality. We used the standard settings, but you may be able to suss out the Vyper's true potential with some tinkering in your slicing software of choice.

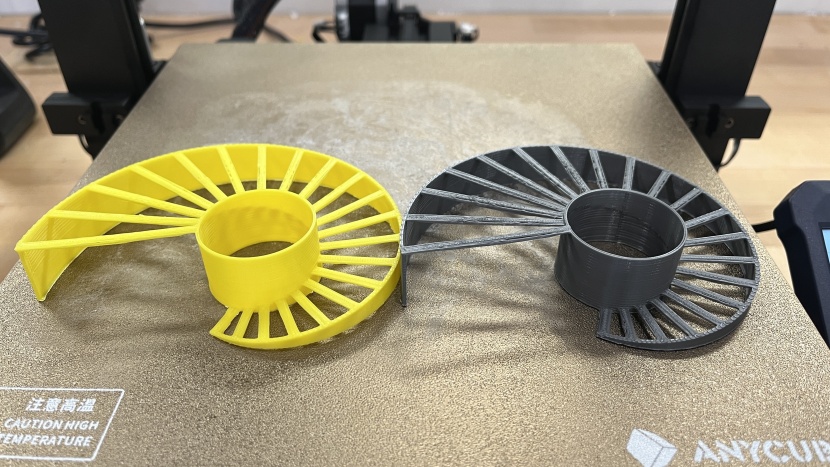

Starting with the famous Benchy - the industry-wide benchmark for assessing and comparing prints, the PLA (gray colored prints in all photos) produced average quality. Solid overall, but it struggled with some steep angles. ABS (yellow prints) fared a bit better, producing a smoother hull and more legible words on the bottom.

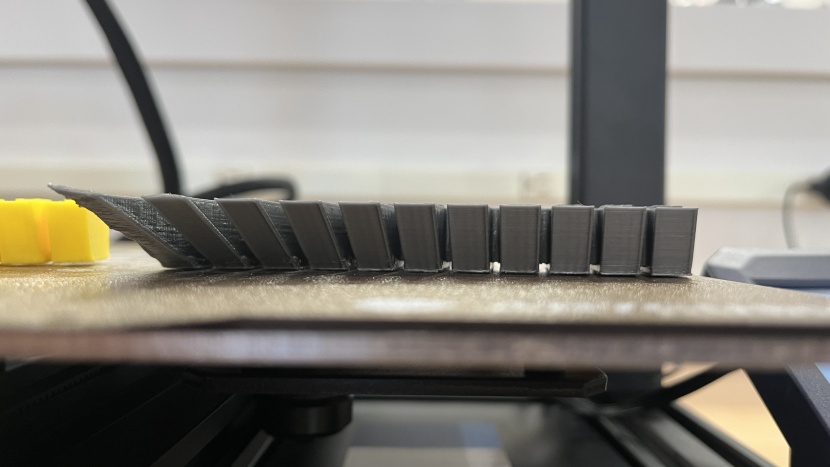

Our PLA bridging test showed some layer and infill separation, along with some general sagging, which improved with ABS. The Eiffel Tower test was perhaps the worst outcome of all models, producing stringy messes, but notably, prints in both types of filaments finished successfully.

When printing models with articulated, print-in-place parts, the Vyper fared much better, though some finer and steeper details had issues (bottoms of the ears and tusks, for example). The Elephant's articulating legs and head were easy enough to break free or came out perfectly separated from the start.

We test dimensional accuracy by printing an opening the size of a nickle, and the Vyper had a near perfect accuracy with PLA, and only slightly worse results with ABS. In our overhang test, only the steepest couple of angles show any distortion.

Thy Anycubic was able to produce good-quality standard, low-poly figurines. Minor issues showed up near small points and fine details like fingers on tiny hands, but the rest of the prints were smooth.

A spiral vase showcases the best of what the Vyper can produce. Our print had consistently thin walls and precise geometry.

When temporary supports were needed for large overhangs, they stuck to the main print in some locations enough that we needed pliers to remove them. This issue can also be remedied by making adjustments with your slicer.

Ease of Use

Ease of Use is one metric where the Anycubic Vyper truly excels. The touchscreen UX is simple and straightforward, and it has an auto-leveling feature that is still not common among printers, especially in this price range.

Setup takes less than 30 minutes, and the printer comes with a built-in tool tray with everything you need. The small bit of assembly that is required consists of attaching the gantry with two screws on each side, a few screws to attach the LCD screen, snapping on the filament roll holder, and plugging in six wiring harness connections. That's it - check out Anycubics unboxing video and see for yourself. Just make sure to check which voltage it's set to — ours came set to 220v, and we had to manually switch to 120v here in the US before turning it on.

The auto-leveling program isn't just a gimmick either. For most FDM (filament-based) printers on the market, leveling the print bed, which simultaneously sets its 1st layer gap, is still a manual step. But it's a crucial step for getting good print adhesion, which is why the Vyper's auto-leveling feature is so great — it takes the guesswork out of the process. The leveling program takes about seven minutes to run and checks 16 points on the bed's surface. Afterward, we found that no further tinkering was needed in most cases for good print adhesion.

The LCD screen features simple menus and a smooth enough UI that we had no complaints. It is worth noting that it only displays print time elapsed, not how much time is left. It did, however, show a real-time percentage complete. Changing the filament is quick and painless, though feeding it through the filament detector can be slightly tricky. The only major annoyance with the Vyper's ease of use is that the prints must be loaded onto an SD card to transfer to the machine. It has no onboard memory, no WiFi capability, and no USB thumb drive port.

Print Capabilities

As mentioned, the Vyper houses effective tech and impressive specs for its price point. The print bed is set up for successful adhesion every time, the larger-than-average build volume of 245mm x 245mm x 260mm is nothing to sneeze at, and it works with non-proprietary software.

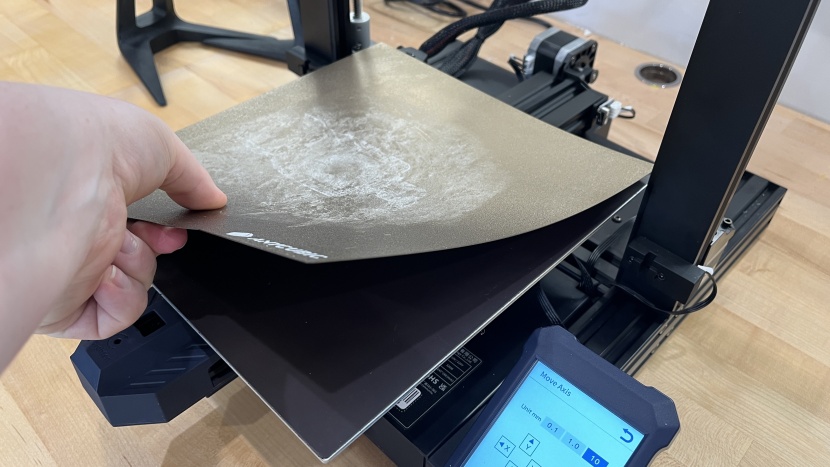

Getting a print to properly adhere to the print bed is a critical and often annoying dance. As mentioned, the Vyper has a useful auto-leveling feature to help with this. It also has a heated bed (standard on FDM printers these days) and a special coating that Anycubic added to the spring steel bed. Both seem to help. But not to worry; removing the print after it's done is a cinch. The bed is both removable and flexible, so simply pop it off and give it a flex. It's held securely in place magnetically, and these kinds of removable beds are a great (not especially common) upgrade.

The Vyper has a max nozzle temperature is 260°C, while the bed maxes at 110°C. It takes all standard and some exotic filaments that we tried (including wood fiber PLA), and it printed them smoothly via a double-sided gear extruder. It also has three fans to help with print warping — one to stabilize the extruder temp and two to cool the print while building.

The Vyper does not require proprietary tech to slice or run. Specifically, it works with hobbyist freeware darling Cura, or if you need a more powerful slicing software, it's also supported by Simplify3D.

Support

Anycubic has a dedicated Vyper-specific support page and responded when we reached out for help, though not as timely as we would have liked. Its warranty is also not industry-leading, but it sells key replacements at an affordable price, with plenty of helpful videos to aid in doing so.

Anycubic is China-based and does not appear to have any real-time way to contact customer service. The company's support process is ticket-based, and there's no number or chat service we could find. However, the support team did respond to an email inquiry and seemed knowledgeable and helpful. We feigned a problem about excessive burning with our ABS prints, and they suggested the culprit was likely that the print head temp was too high and asked for our slicing settings to help correct the situation — an appropriate direction.

The Vyper-specific dedicated support page is genuinely helpful though. It covers topics from the current firmware version to videos on how to replace commonly replaced parts. This is useful because its warranty could be better. The warranty covers issues with the print head for up to three months, while issues with the print bed (the Ultrabase) and other components are covered for up to 12 months.

Should you buy the Anycubic Vyper?

The Anycubic Vyper is a great choice for a variety of users. It features some tech usually only found on pricier options, is among the easiest and most headache-free printers to set up and run, and has some good support to help make your prints look flawless. Bottom line, The Vyper is good for what it is — a good introductory FDM printer that's easier to use than most on the market. If you've been waiting for a great FDM option to fall into this price tier, look no further.

What other 3D printer should you consider?

If top-notch print quality is what you require from your desktop printer, then going with a resin-based printer may be for you. The Elegoo Saturn 2 is a great choice for top-notch print quality at an affordable price tag. Just remember that resin printers are notoriously messy and annoying to post-cure, so if ease of use is equally important for you, FDM (filament-based) printers are the way to go. The best FDM printer for print quality we've tested is the Bambu Lab P1P, but you pay a handsome price for that luxury. On the other end of the spectrum, the Creality 3D Ender 3 Pro is a good option for even tighter budgets, but know the print quality will take some time to dial in, and it's not quite as easy to use as other FDM printers available.