Our Verdict

Our Analysis and Test Results

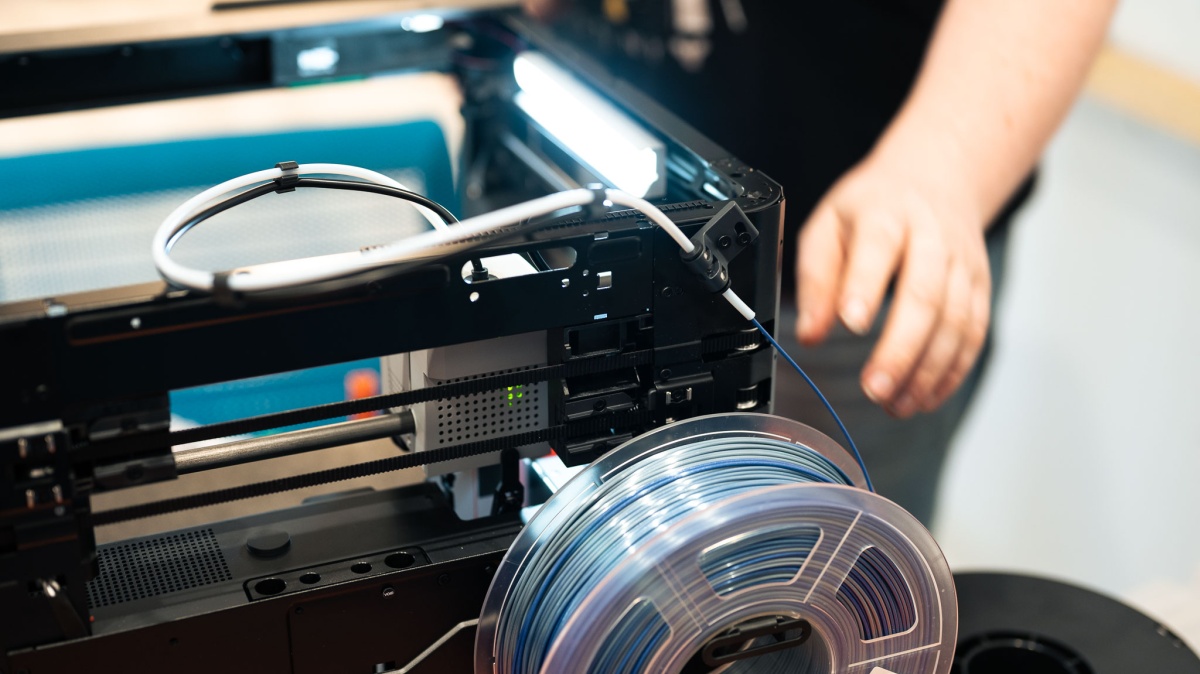

Bambu Lab is a relative newcomer to the 3D Printer field, but its quality and print speed are already becoming well known. Its higher-end X1 series has a generally good reputation, which carries over to this mid-range product and the smaller, more budget offering, the Bambu Lab A1 mini as well.

Print Quality

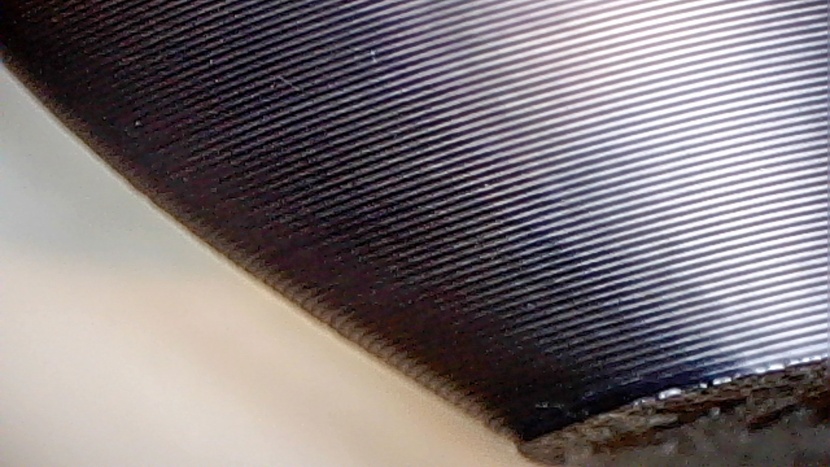

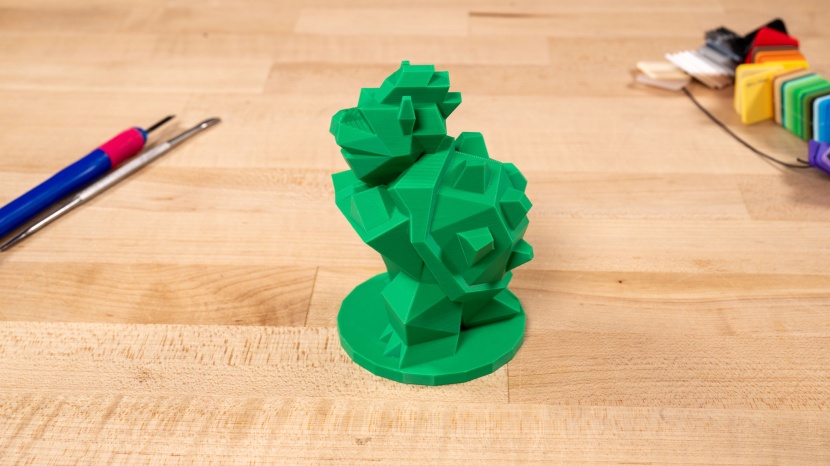

Bottom line: the quality achieved by the Lab P1P across our panel of prints resulted in one of the best scores ever, especially for an FDM option. We looked for common issues, including bridging & overhangs, wobbles and waves on flat surfaces, and extrusion consistency, and the P1P showed nearly flawless finishes on most projects.

It produced flat sides and sharp corners on our XYZ Calibration Cube, showing a super consistent smoothness with minimal stringy artifacts. The inset lettering on the cube was crisp, we didn't detect any ghosting, and the overall surface quality was fantastic. On the Z-tower, we observed some slight wobbles near the top of the tower, but overall, it shared the same crisp angles as found on the cube.

In our vase test, the Bambu achieved near-flawless surface quality in this print without any sign of pronounced stepping between layers. You can see that the extrusion was well controlled because (nearly) all layers are well fused; we only found a single pinhole when we checked for watertightness.

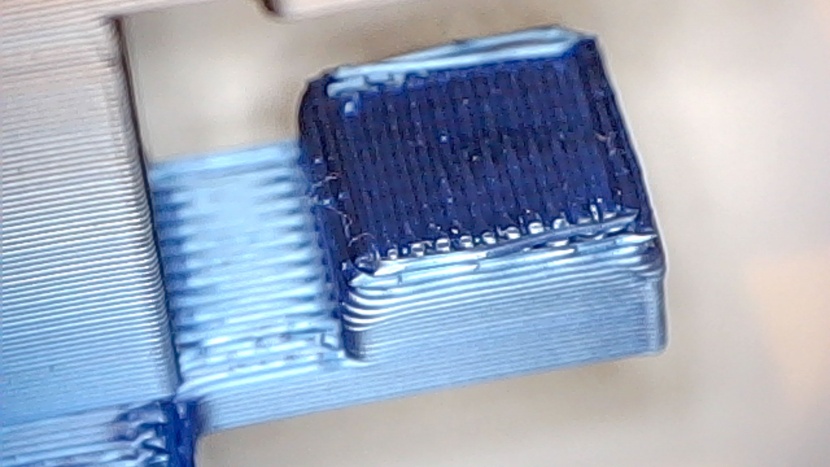

When testing for bridging and overhang ability, the P1P had no problem with gaps up to 20mm and 30mm. Some drooping and separation were seen at 40mm and higher, and supports will be necessary for any spans wider than this. Overhangs started to show stepping and reduced smoothness at around a 50° angle, which is about average. When support was needed, we found the default generation from the slicer (the print prep software) to work well. The supports were easy to remove by hand, and generally left behind a decent surface, with just a small, convex, rounded shape at the removal site.

When testing dimensional accuracy, we use a coin fit test. The P1P printed a cavity almost precisely the size of a nickel, although the X/Y surfaces were a little undersized and had some not-so-ideal bridging on the top. We also check the functionality of moving parts and the minimum clearance between gaps. After printing a small spinning toy with gaps as small as 0.15mm, tester Graham Faulknor said, “Some of the smaller gaps did need to be pried apart a bit, but when that was done, the whole toy moved freely without further tinkering.”

To round things out, the time-honored Benchy test showed a print with clean and consistent surface quality; our only complaint was some fine hair-like strings left clinging to the overhangs like spiderwebs. Slight imperfections kike this can be managed through dialing in your slicer settings, but the P1P is solid even when left with its default settings.

Ease of Use

Bambu Lab clearly spent a lot of time and effort making the software and hardware execution side of things a painless experience. We appreciated the inclusion of an automatic bed leveling program and an onboard camera. These are common features, but they are not universal (or universally well-designed), and they make the P1P that much nicer to use.

The initial build of the machine is simple and easy. The unit arrives almost fully assembled with only a few of the more delicate parts, like the touch screen, packaged separately. From the time we opened the box, it was only 15 minutes before we were able to press 'start' on our first test print.

The slicing software is proprietary, which is a trend we don't love to see, but we expect it to become the norm as the industry continues to mature. Luckily, the proprietary Bambu Studio software is one of the better options we've played around with. A prominent calibration table helps ensure things are ready for every print, and it is supplemented by some robust adjustment settings that you can fine-tune even further. Overall, the user experience feels straightforward and clean.

Getting your prints from your slicer to the printer can be done via WiFi or transferred offline with a microSD card. Oddly, menu navigation involves a small, pixelated screen and a few buttons, which feels a little less polished than the rest of the experience.

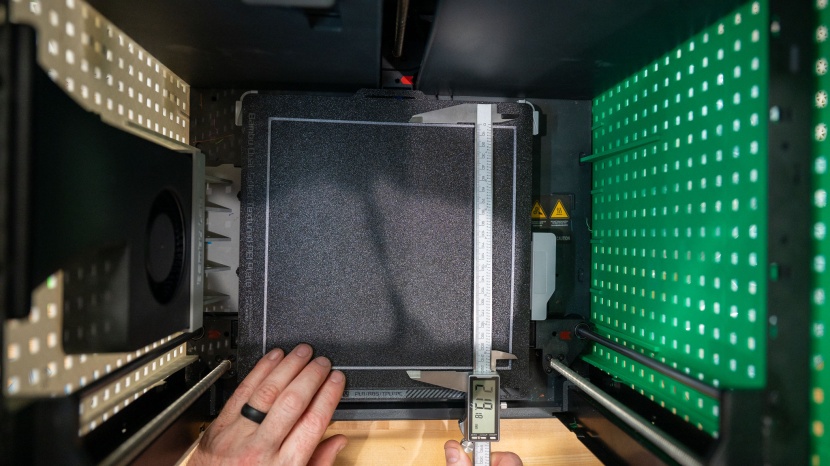

The print bed is perhaps the most well-designed and evenly heated that we've used, as confirmed through a thermal camera. In addition to even heating, the top plate is removable and flexible, so prints can also be removed in a snap. We didn't have a hint of print adhesion or warping failures throughout the whole process.

Print Capabilities

Our first look at the advertised specs on the P1P was eye-popping. A 256mm x 256mm x 256mm build volume is just about the largest we've seen on such an affordable FDM consumer product.

In practice, attempting to use the full X/Y build size was an interesting experience. It wouldn't go past 220mm x 220mm, over which it says the 'risk of collisions' is too high. Eventually, we were able to override this setting, and the full 256mm x 256mm was achievable.

We were also happy to see a maximum extruder temperature of 300°C. For a long time, 260°C has been the unofficial default in the industry (standard PLA prints at about 220°C), but users are beginning to seek out specialty filaments, which usually require higher melting temps. Further heat control also helps ensure better results with these exotic materials. Luckily, the P1P's 'CoreXY structure' (basically meaning it's built like a cube) can be fully enclosed with a bit of user modification, providing a more temperature-stable environment in which to build.

The P1P is advertised as having a max print speed of 500mm/s (nearly 20 inches per second), which… is absolutely too fast. In our opinion, this is more of a marketing gimmick than anything. Even with the proven print accuracy we determined, there is no way we'd have confidence that a speeding print head wouldn't catch a lip and ram a taller print over. Anything over about 90mm/s is playing with fire, but the capability is there if you're brave enough to try.

We're more interested in two other features: the camera and the multicolor accessory upgrade. Our tester remarks, “The camera is nothing special resolution-wise, but I had fun using it to get some cool time-lapses.” Better, though, is that with the paired app, you can remotely monitor your print and stop it if needed, for example, to prevent material waste or potential damage to the machine in the event of a failure.

Many users will be interested in the P1P and other Bambu products like the Bambu Lab A1 mini because of their multicolor accessories, which they call AMS (Automatic Material System). These can be spendy, but auto-changing filament for multiple colors is a tough challenge, and at least for now, Bambu Lab seems to have done a decent job addressing the market desire.

Support

Support is an area where we've seen some rapid improvement from Bambu in the last year or so. A very comprehensive support wiki covering darn near every topic you could want is among the best in the industry. Complimenting this resource is a fervent and dedicated community of users with collective knowledge accessible via a community forum. Poke around these resources a bit and see if the charm hits you the same way it did us.

As far as traditional customer support, we couldn't find a US-based phone number, but they do have a live chat feature. The average response time when we reached out over email was fine; a day or two between replies was standard. The warranties are a mixed bag: one year for the US and two for the EU, supplemented by a 14-day no-questions-asked return policy. However, the warranty was reduced to just three months for some notable things, like the extruder head and the AMS filament changer.

Should You Buy the Bambu P1P?

So, is the Bambu Lab P1P worth it? We certainly think so. Although it is a bit on the pricey side, it has everything you could want in an FDM printer: great print quality, a polished user experience, and some genuinely uncommon and useful feature upgrades. It is hard to find performance this good in all areas in a single machine, and we thing any user will be satisfied with the prints they can make with the P1P.

What Other 3D Printer Should You Consider?

For FDM printers, you're going to be hard-pressed to find a better option than the P1P. But for those with tighter budgets, the much more affordable AnkerMake M5C offers competitive performance at a more palatable price. The M5c's brother, the M5, is the closest to the P1P in terms of bells and whistles, but for (relatively) affordable multicolor printing, you'll want to take a look at the A1 mini. If you're on the hunt for finer details, this is better achieved with a resin-based printer, and you can pop on over to the Anycubic Photon Mono 2 review and have a look-see.

| Awards | Best Overall 3D Printer |

|---|---|

| Price | $539 List |

Overall Score  |

|

| Star Rating | |

| Bottom Line | A high performer in every metric, you can't go wrong with this polished product |

| Pros | Easy setup, camera, multicolor upgradable |

| Cons | Proprietary slicer, spendy |

| Rating Categories | Bambu Lab P1P |

| Print Quality (40%) | |

| Ease of Use (30%) | |

| Print Capabilities (20%) | |

| Support (10%) | |

| Specifications | Bambu Lab P1P |

| Time to Print a Benchy | 45.30 min |

| Measured Effective Bed Size | 220mm x 220mm |

| Bed Temp Gradient | 1.1° C |

| Maximum Extruder Temperature | 300 C |

| Screen Resolutiuon | N/A |

| Compatible Materials | Ideal: PLA, PETG, TPU, PVA, PET Capable (Enclosure required): PA, PC, ABS, ASA Not Recommended: Carbon/Glass Fiber Reinforced Polymer |

| Build Volume (X x Y x Z) | 256mm x 256mm x 256mm |

| Overall Size | 15.2" x 15.2" x 18.0" |

| Self Leveling Bed | Yes |