Our Verdict

Our Analysis and Test Results

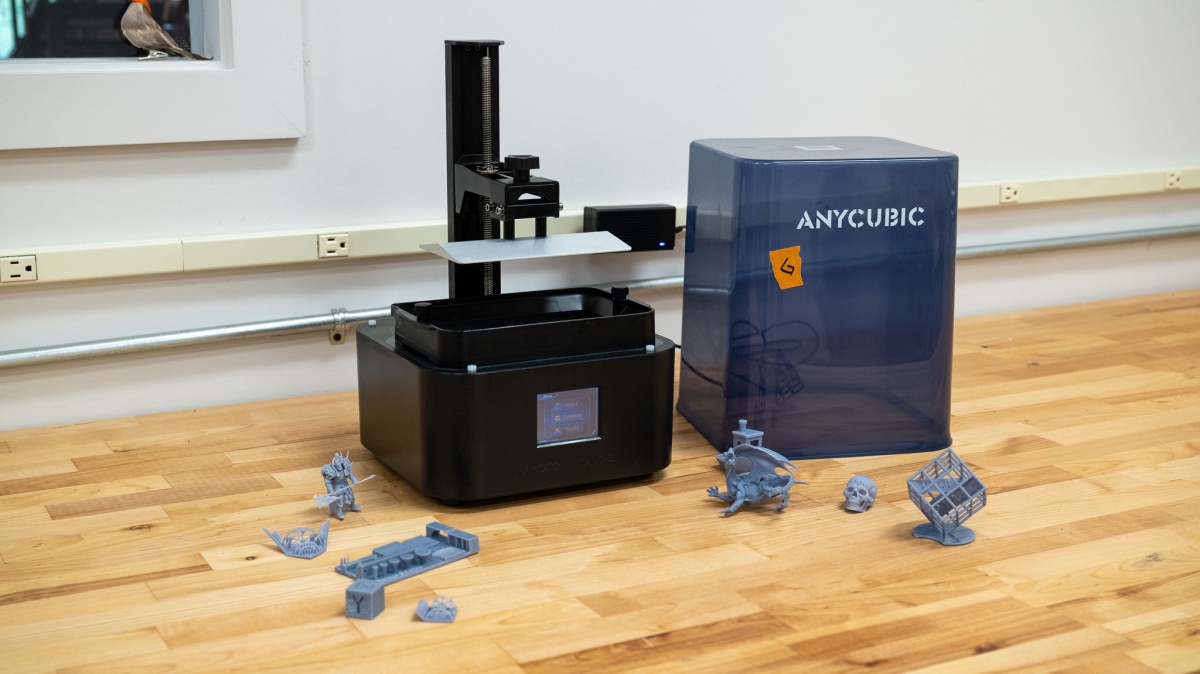

The vast majority of hobbyist 3D printers available today are FDM (fused deposition modeling). But as the 3D printer market grows, resin (also known as SLA or stereolithography) printing options like the Mono 2 are beginning to gain popularity with certain crowds. Super detailed, smaller-size prints generally align better with SLA technology, and if this is the type of design you plan to work with, it could be a good option.

Print Quality

Print quality is what sets SLA printers apart. The technology behind SLA printers is fascinating, but the TLDR version is that SLA printers use a high-resolution screen to flash an image through a goopy, raw resin, to cure your design layer by layer into a 3D structure. The resolution here fundamentally beats the resolution possible via melted plastic through a nozzle (FDM), resulting in more detailed prints with fewer errors.

Indeed, the Mono 2 produced some of the most detailed prints in our lineup. Delicate, hyper-detailed models were carried out flawlessly, as shown in our lattice skull test. When looking for issues in surface quality, overhangs, and bridging over long spans — common problem areas with FDM printers — we couldn't find them. Our testers say, “These are all nearly nonexistent issues for the Mono 2; gravity is much less of a factor here.” Intricate prints are not your concern; that said, size (and material cost) might be.

While gravity is much less of a problem, a support structure is still needed with some fragile geometries. Again, the Mono 2 shines here. Supports break away easily, and the surfaces where they were attached show barely any signs of their existence.

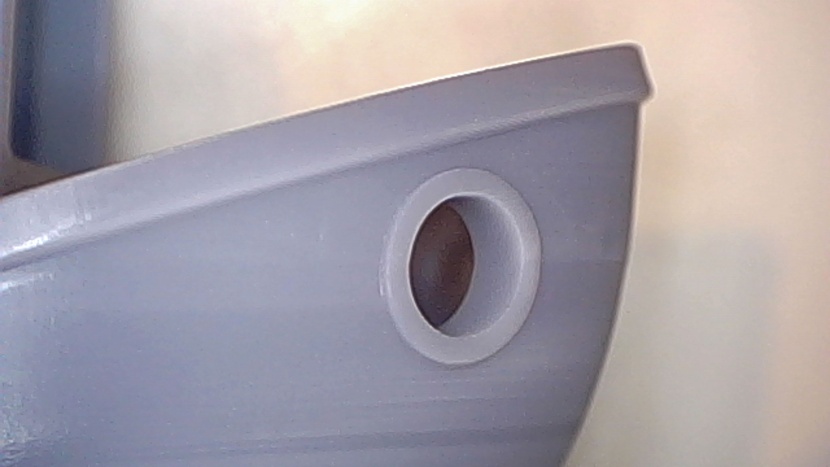

Ultimately, the benefits of resin are clear when evaluating our classic Benchy print (the standard tugboat design used throughout the community to suss out issues and evaluate quality). We were hard-pressed to find any flaws. We will note that print times are considerably longer here than in other tested machines — 175.5 minutes to print vs. the group average of 74.9 minutes.

Ease of Use

Setting up the Photon Mono 2 is easy, both on the physical machine and when getting your prints ready on the software end of things. But, according to tester Graham Faulknor, “the post-curing process is nothing less than a pain in the butt.”

A 6.4 out of 10 score (just slightly below average) reflects this major dichotomy. On one hand, we have nothing but wonderful things to say about the setup out of the box. We needed 11 minutes to get the Mono 2 up and running, which is just about the fastest setup we've ever handled. Removing the packaging, installing the screen guard, and leveling the main platform are the only steps needed.

The slicing software, Photon Workshop, is also a joy to use. It's simple, with relatively few settings to adjust (inherent with SLA), and Anycubic doesn't try to make it more complicated than it needs to be. The unit includes a small touch screen, which we wish were a bit bigger to avoid the rogue fat finger press.

In a sense, Anycubic has made the parts of the process they can control relatively painless. But the other side of the coin is the post-processing. The curing process is something we have not seen any consumer-level resin printer manage to do well or even really attempt to automate. After a print is done, the bed raises and drips the majority of the uncured stuff off. Your print then needs to be washed and cured with UV light in a separate chamber. Anycubic, of course, sells these kits separately — a cleaning kit and an upgraded combo wash and cure chamber.

The resin itself is a thick, smelly, sticky mess. As long as the UV blocking cap is securely in place, it can be left in the tank for a few months between prints, but emptying it for longer storage is a tense procedure. With some practice, this whole process can be done relatively quickly, cleanly, and reliably, but anyone considering a resin printer needs to be aware of what they're getting into.

Print Capabilities

Resin printers usually have smaller build volumes, and the Mono 2 is no exception. The claimed build dimensions are 143mm x 89mm x 165mm, however, our team found that the largest X/Y dimensions the software would allow is actually a fair bit smaller at 137 x 80mm — almost 14% smaller than advertised.

Essentially, a model no bigger than 3.15" in the smallest dimension is possible on the Photon Mono 2. The LCD screen resolution is 4k (4096 x 2560 pixels to be exact), but if we're being honest, that's on the low end for printers these days.

One thing we like is that the Mono 2 doesn't get stuck in the proprietary materials trap, and it supports most resins available on the market these days. Resins are continuing to evolve, and having access to water-soluble, plant-based, and ABS-like options is really nice.

Support

Anycubic is another Chinese manufacturer in the 3D printer space, but it has been around longer than most; their first 3D printer was released in 2015. Thus, their support library and materials are mature and cover pretty close to everything you could want to know.

The Mono 2 manual is available online through their comprehensive help center and a dedicated wiki is available for anything else you may want to know. The manual is relatively short and sweet, with much of the space dedicated to dialing in settings and troubleshooting, which goes to show how simple and easy it is to use this product.

We couldn't find a live phone number to call. Like many offshore companies, email contact is the standard, and they usually get back within 24 hours. A standard 1-year limited warranty is extended to all of Anycubic's products, as well as a 14-day no-questions-asked or 30-day sales-determined return window.

Should You Buy the Anycubic Photon Mono 2?

For a resin printer, the Mono 2 is a very affordable, very capable option. No muss and fuss; it works as advertised and without any glaring concerns. The favorite Dungeon Master or Warhammer enthusiast in your life would be thrilled to get their hands on the Mono 2 if they don't already have a printer at home. A more casual user may prefer the ease and cleanliness that an FDM option provides, though.

What Other 3D Printer Should You Consider?

If you've made it this far, an SLA resin printer may indeed be what you're looking for, but perhaps a larger build volume (for product prototypes?) may interest you. The Elegoo Neptune 4 Pro fits that bill, with a build volume 6.6x bigger than the Mono 2. On the FDM side, great options exist from Bambu Lab, such as the A1 mini, and AnkerMake, such as the M5C. On the affordable (and smaller) end of things, check out the Entina Tina2.

| Awards | Best Value Resin Printer |

|---|---|

| Price | $209 List |

Overall Score  |

|

| Star Rating | |

| Bottom Line | An affordable, no frills resin printer that's easy to setup and run |

| Pros | Painless to get going, stellar surface quality |

| Cons | Very slow, needs washing and curing kits, messy |

| Rating Categories | Anycubic Photon Mono 2 |

| Print Quality (40%) | |

| Ease of Use (30%) | |

| Print Capabilities (20%) | |

| Support (10%) | |

| Specifications | Anycubic Photon Mono 2 |

| Time to Print a Benchy | 175.50 min |

| Measured Effective Bed Size | 137mm x 80mm |

| Bed Temp Gradient | N/A |

| Maximum Extruder Temperature | N/A |

| Screen Resolutiuon | 4096 x 2560 |

| Compatible Materials | Supports most resins on the market (water-washable, standard, ABS-like, plant-based, etc.) |

| Build Volume (X x Y x Z) | 143mm x 89mm x 165mm |

| Overall Size | 15.4" x 9.0" x 9.3" |

| Self Leveling Bed | No |